OEM/ODM Manufacturer Steel Ceiling Grid - Lay-In Fine Fissured Ceiling Suspended System White Ceiling Grid – Beihua

OEM/ODM Manufacturer Steel Ceiling Grid - Lay-In Fine Fissured Ceiling Suspended System White Ceiling Grid – Beihua Detail:

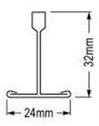

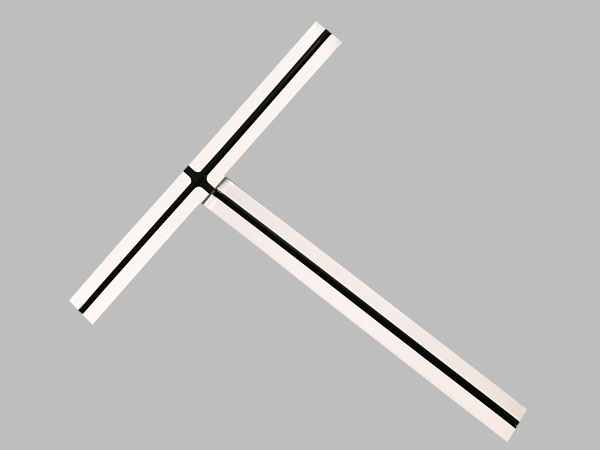

Flat ceiling grid

The decorative surface is made of matte coated steel strip, with fine texture and no color difference.

Multi-roller molding, smooth surface; high strength, easy and quick installation.

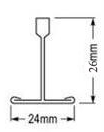

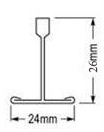

Narrow flat ceiling grid

Simple and elegant shape, excellent shock resistance. Light weight, easy and quick installation.

Groove-type ceiling grid

Groove shape is available in black and white, with strong three-dimensional effect.

Easy installation, firm system.

Exposed ceiling grid

Using double-sided color coated steel strip as raw material, soft color, clear lines, strong three-dimensional effect has high dimensional accuracy and close coordination. It can be used with metal ceilings and mineral wool sound-absorbing panels. It is a classic product for indoor ceilings in modern buildings.

|

Description |

Length |

Height |

Width |

|

|

Flat T24 Ceiling Grid Main Tee |

3600mm/3660mm |

32mm |

24mm |

|

|

Flat T24 Ceiling Grid Long Cross Tee |

1200mm/1220mm |

26mm |

24mm |

|

|

Flat T24 Ceiling Grid Short Cross Tee |

600mm/610mm |

26mm |

24mm |

|

|

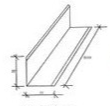

Wall Angle |

3000mm |

22mm |

22mm |

Installation conditions

1. During structural construction, the joints of the cast-in-place concrete floor or precast concrete floor should be pre-embedded with φ6~φ10 reinforced concrete suspenders according to the requirements of the shot meter. When the shot meter is not required, the steel bar hanger shall be embedded according to the arrangement position of the large keel rod, the general spacing is 900~1200mm.

2. When the wall pillars of the suspended ceiling room are brickwork, they should be pre-embedded with anticorrosive wood bricks at the elevation of the ceiling along the walls and pillars. The distance between the walls is 900~1200mm, and each side of the pillars should be buried. More than two wooden bricks.

3. After installing the various pipelines and ventilation channels in the ceiling, determine the position of the light, the ventilation opening and various openings.

4. All kinds of materials are complete.

5. The wall and ground wet work projects should be completed before the ceiling cover panel is installed.

6. Set up the shelf of the ceiling construction operation platform.

7. Before the large-area construction of the lacquered skeleton ceiling, a sample room should be made. The curvature of the ceiling, the structure treatment of the light trough, the vent, the division and the fixing method, etc. should be tested and installed and approved before the large area construction.

Product detail pictures:

Related Product Guide:

"Control the quality by the details, show the strength by quality". Our company has strived to establish a highly efficient and stable staff team and explored an effective quality control process for OEM/ODM Manufacturer Steel Ceiling Grid - Lay-In Fine Fissured Ceiling Suspended System White Ceiling Grid – Beihua , The product will supply to all over the world, such as: Bangkok, Serbia, Mauritania, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. We have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.