Eps and Xps sound like the same thing, but they are actually two different products. Although the raw materials are all polystyrene, the production process is completely different. Although the characteristics of the products are similar, there are still some differences.

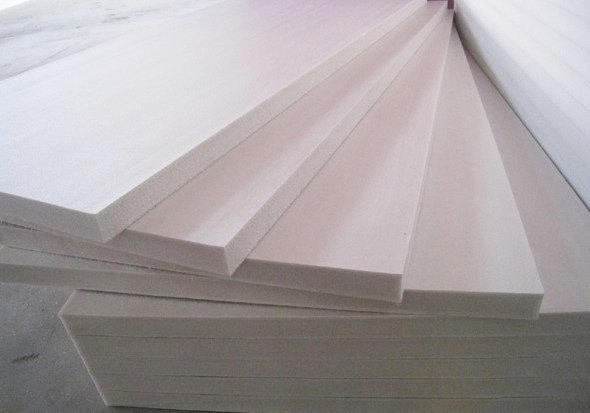

Eps is the foamed product of polystyrene, and xps is extruded after mixing with other raw materials. The product process is different, so the internal structure of eps and xps boards is different, resulting in some differences in product performance. Although the raw materials are all polystyrene, the product density, compressive strength, and flame retardant properties are similar, but the air permeability and water absorption are different. Because the xps board is extruded, its internal structure closed cell rate is stronger than that of eps. Because of this, the air permeability of the xps board will be worse than that of eps. However, since the xps board is extruded, its compressive performance is excellent, which is better than that of the eps board. Therefore, the xps board will have a great advantage over the eps when it is used for building insulation, floor insulation and other applications. . Usually, the two can be substituted for each other if only for ordinary insulation.

In terms of service life, the general xps board has good compressive performance, but it is more brittle than eps, and the flexibility of eps board is better than that of xps board, both of which have their own advantages and disadvantages. In the domestic construction process, the eps board will be used more, because it is formed by a mold, and the shape can be made into various shapes, but the xps board is extruded, and the shape is relatively simple, not as much as the eps board.

Xps board and rock wool, glass wool board are both great insulation material, they have different usage for construction process, contact us for more details.

Post time: Feb-16-2022