1. The treatment of the base wall and its cement mortar leveling layer and the installation of embedded parts have been completed. The necessary construction equipment and labor protection supplies should be ready. The special scaffolding for construction shall be erected firmly and passed the safety inspection. The distance between the scaffolding poles and horizontal poles and the wall and corners should meet the construction requirements.

2. The base wall should be solid and flat, and the surface should be dry, without cracking, hollowing, looseness or efflorescence. The bonding strength, flatness and verticality of the cement mortar leveling layer should conform to (Code for Acceptance of Building Decoration Engineering Quality) GB50210 Requirements for the quality of ordinary plastering projects.

3.During the construction of the external thermal insulation of rock wool board, the base course and construction environment temperature shall not be constructed when the temperature is lower than 5℃. Construction is not allowed in strong winds and rain and snow weathers above level five. During and after construction, effective measures should be taken to prevent rain erosion and hot sun exposure, and a protective layer should be made in time. In case of sudden rain during construction, measures should be taken to prevent rainwater from washing the walls; during winter construction, anti-freezing measures should be taken in accordance with relevant standards.

4. Before large-scale construction, the same materials, construction methods and craftsmanship should be used on site to make model walls according to regulations, and construction can only be carried out after confirmation by the relevant parties. When using rock wool board for construction, the operator should wear protective equipment, do a good job of occupational health protection, and pay attention to construction safety.

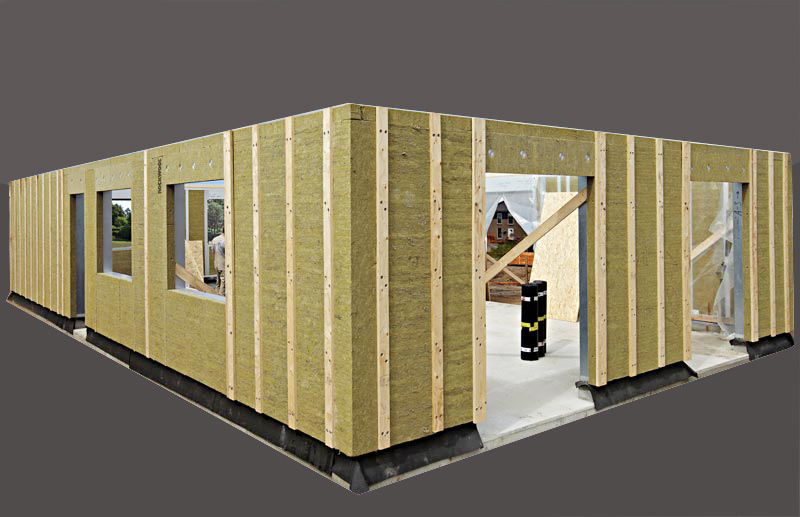

5. The materials that must be inspected for the external thermal insulation system of rock wool board should be sent to a qualified testing organization for testing, and can be used only after the testing is qualified. The sticking method or point sticking method should be adopted to stick the rock wool board, and the glue area should not be less than 50%.

6. After the rock wool board is finished with the adhesive, the lower end of the insulation board should be pasted with the base layer. The rock wool board should be laid horizontally from bottom to top, and the side laying and anchoring methods should be adopted for fixing. Close naturally, and the gap between the plates shall not be greater than 2mm. If the seam width is 2mm, it should be filled with thermal insulation materials, adjacent boards should be flush, and the height difference between the boards should not be greater than 1.5mm.

7. All the wall pipelines and components that can reach the rock wool board shall be filled with the same material at the exit part and then be waterproof and sealed. If the veneer layer is found to fall off during the construction process, it shall be fixed in time by bonding or anchoring with anchors, and the exterior veneer layer shall be constructed in time.

Post time: Sep-17-2021