At present, glass wool is a kind of thermal insulation material with wide application range and excellent performance. In the field of construction engineering steel structure, glass wool is often used as filling wall, especially steel structure glass wool has fluffy and intertwined fibers with a large number of tiny voids. It is a typical porous sound-absorbing material with good sound absorption and noise reduction characteristics. It is widely used in construction engineering KTV, opera house, conference room and other fields. But when using steel structure glass wool, we need to pay attention to it, we must put moisture-proof veneer on the glass wool.

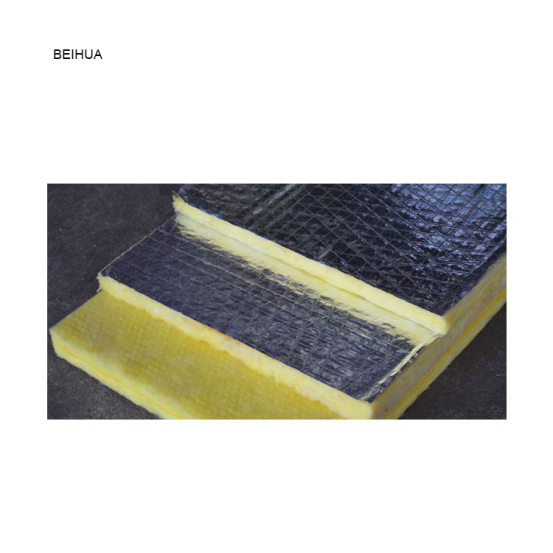

Facing aluminum foil or pvc on the glass wool’s surface has a lot of advantages, for example.

1. Preventing water vapor from penetrating into glass wool

After the glass wool is laminated with aluminum foil, the tightness between the aluminum foil metal molecules can effectively prevent the penetration of water molecules and water vapor, so that the water vapor penetration function is better.

2. Keeping the glass wool intact

After the glass wool is veneered, a moisture-proof veneer is attached to the surface layer, which can effectively prevent the glass fiber from falling off and forming flying flocks, which affects the construction progress.

3. Blocking the exposure of glass fiber

After the glass wool surface layer is veneered, it can prevent the internal glass fiber from being exposed, and the appearance is more tidy and clean.

4. Enhancing the support of the system

The usage of moisture-proof veneer for steel structure glass wool can effectively prevent steel from being corroded by water vapor, affecting the safety helmet and stability of steel structure buildings, and increasing the support capacity of the steel structure system.

Post time: Jul-19-2021