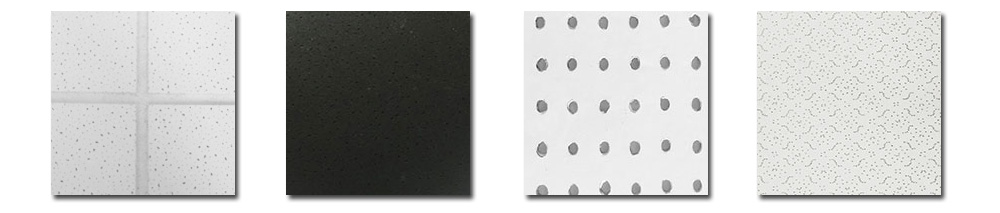

Square Lay-In Ceiling Tiles 2×2 Mineral Fiber Ceiling

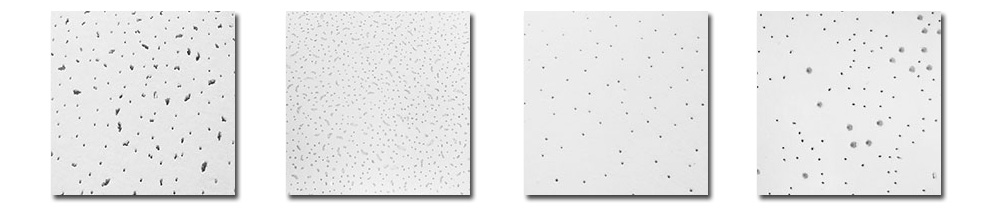

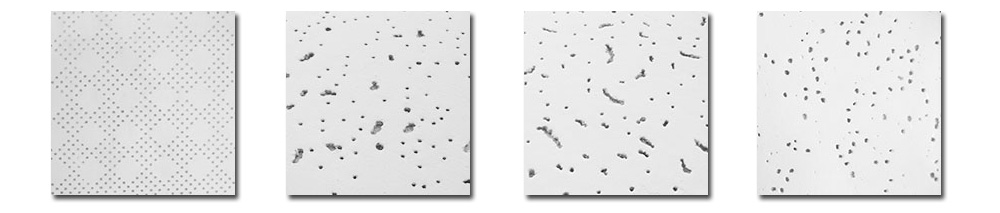

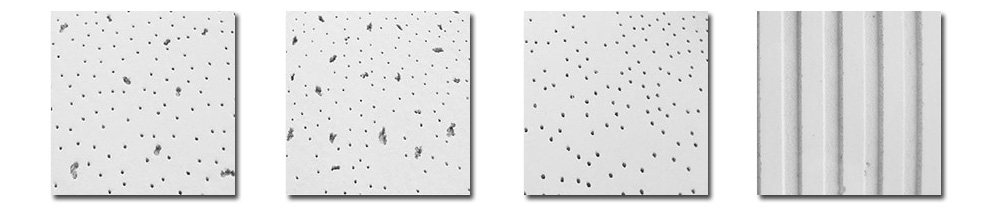

- 1. Excellent decorative effect.

- 2. Good heat insulation performance. The thermal conductivity of mineral wool sound-absorbing panels is very low, and it is a good thermal insulation material, which can make the room warm in winter and cool in summer, and effectively save energy for users.

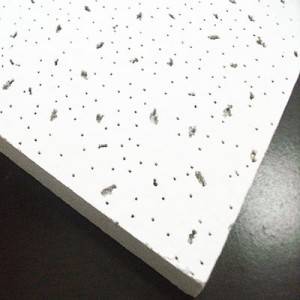

- 3. Sound absorption and noise reduction. The main raw material of the mineral wool sound-absorbing board is ultra-fine mineral wool fiber with a density of 250-300Kg/m3. Therefore, it has a wealth of penetrating micropores, which can effectively absorb sound waves and reduce sound wave reflection, thereby improving indoor sound quality and reducing noise.

- 4. Safety and fire prevention.

- 5. Green environmental protection. The mineral wool sound-absorbing board does not contain harmful substances to the human body.

- 6. Moisture-proof and insulated. Because the mineral wool sound-absorbing board contains a large number of micropores and the specific surface area is relatively large, it can absorb and release water molecules in the air and adjust the indoor air humidity.

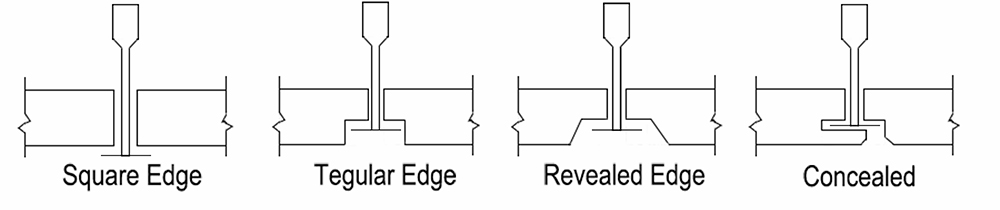

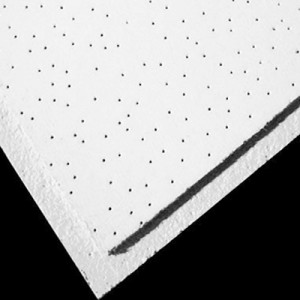

- 7. Simple cutting and easy decoration. The mineral wool sound-absorbing board can be sawed, nailed, planed, and bonded, and can be cut with a general wallpaper knife, so there is no noise during cutting. It has a variety of hoisting methods such as flat sticking, insert sticking, exposed frame, hidden frame, etc., which can combine decorative effects of different artistic styles.

- 8. Wet process, complete the whole process through pulping, Fourdrinier copying, dehydration, slitting, drying, slitting, spraying, finishing and other processes.

- 9. During the transportation of the mineral wool board, pay attention to the integrity of the packaging, moisture-proof and rain-proof, to prevent the board from being damp, which will affect the installation performance.

- 10. The mineral wool board should be lightly loaded and unloaded during the handling process. The board should be laid flat, not vertically, to avoid corner damage.

Write your message here and send it to us