Education Building Ceiling Fire Resistant 2×4

The production process of mineral wool panels is relatively complicated, mainly including wet fourdrinier wire copying, wet rotary screen copying, dry pasting and molding method, semi-dry method, etc. Our company’s automatic production line adopts wet fourdrinier wire forming, through pulping, fourdrinier wire picking, dehydration, slitting, drying, slitting, spraying, and finishing.

1. Put a certain amount of mineral wool into a container and stir with water to separate the cotton from the slag ball. The slag ball sinks to the bottom. The additives such as adhesive and water repellent are mixed and stirred into a slurry according to the ratio, and then it is formed on the fourdrinier machine. In the process, the slurry is filtered, vacuum-absorbed, and extruded into a rough blank of a certain thickness. After cutting, it is dried to form a mineral wool substrate board.

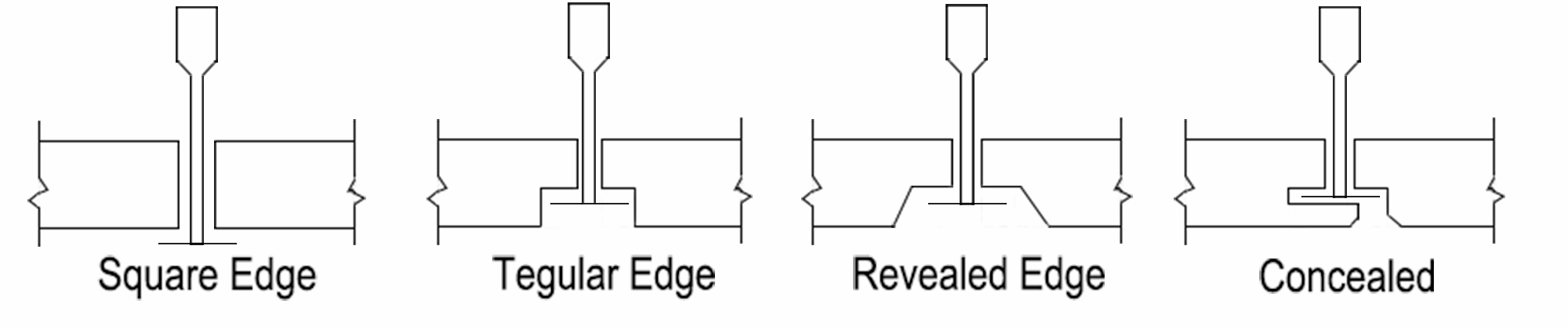

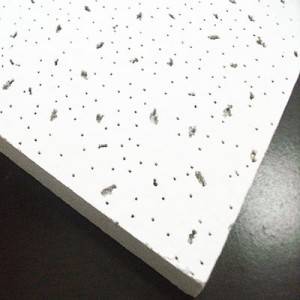

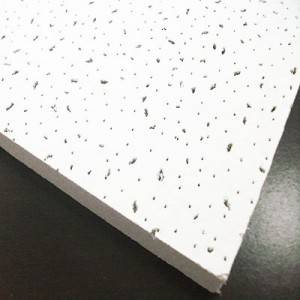

2. The semi-finished product is rolled to produce impervious holes of different sizes and shapes to increase the sound absorption effect, and then finishing the edge , painting, and drying.

The size could be produced at 595x595mm, 600x600mm, 603x603mm, 610x610mm, 625x625mm, 603x1212mm, 595x1195mm, 600x1200mm, etc. Thickness is 9mm, 10mm, 11mm, 12mm, 13mm, 14mm, 15mm, 16mm, 17mm, 18mm, 19mm, 20mm. The surface patterns are pin hole, fine fissured, worms, sand texture, glacier, etc. The mineral wool board can be soundproof, heat-insulated, and fire-proof. Any product does not contain asbestos, is harmless to the human body and has the function of anti-sagging. It is widely used in various building ceilings and wall-mounted interior decoration; such as hotels, restaurants, theaters, shopping malls, offices, broadcasting rooms, studios, computer rooms and industrial buildings.

Precautions for installing mineral wool board

1. During the installation of the mineral wool board, the room should be sealed to prevent humid air from entering, in case mineral wool board sink.

2. During the installation process, workers should wear clean gloves to keep the surface of the mineral wool board clean.