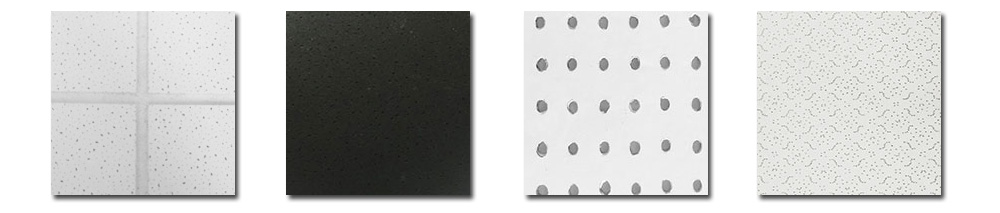

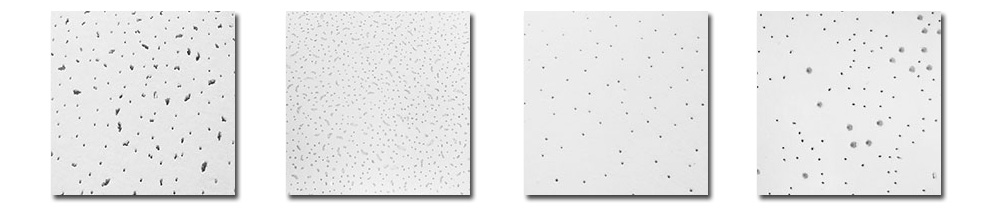

Smooth Ceiling Mineral Fiber Ceiling Non-Directional Ceiling Tile

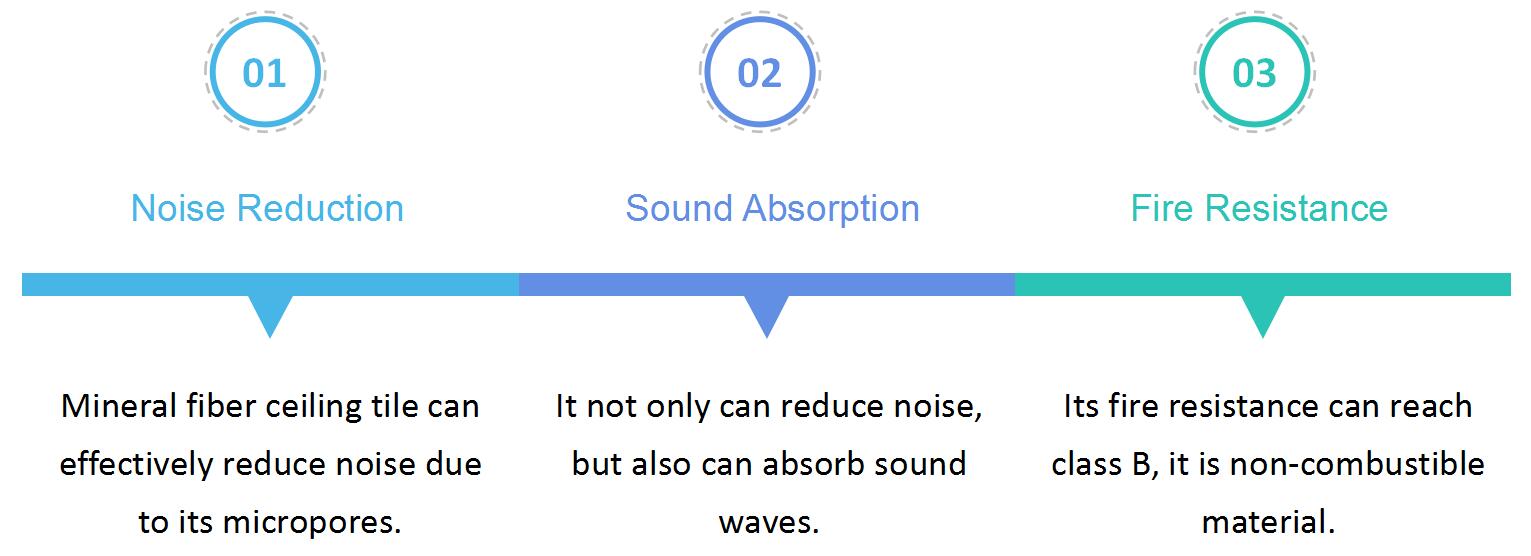

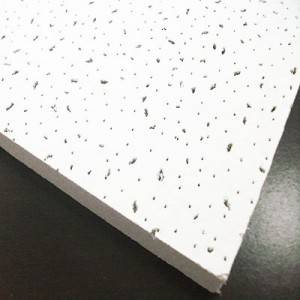

1. Noise reduction: The mineral wool board uses mineral wool as the main raw material for production, and the mineral wool has developed micropores, which reduces sound wave reflection, eliminates echo, and isolates the noise transmitted by the floor.

2. Sound absorption: Mineral wool board is a kind of porous material, which is composed of numerous micropores. When used in interior decoration, the average sound absorption rate can reach 0.5 or more, suitable for offices, schools, shopping malls and other places.

3. Fire resistance: Fire prevention is the primary issue in the design of modern public buildings and high-rise buildings. The mineral wool board is made of non-combustible mineral wool as the main raw material. It will not burn when a fire occurs, it is the most ideal fireproof ceiling material.

Construction steps and technical requirements

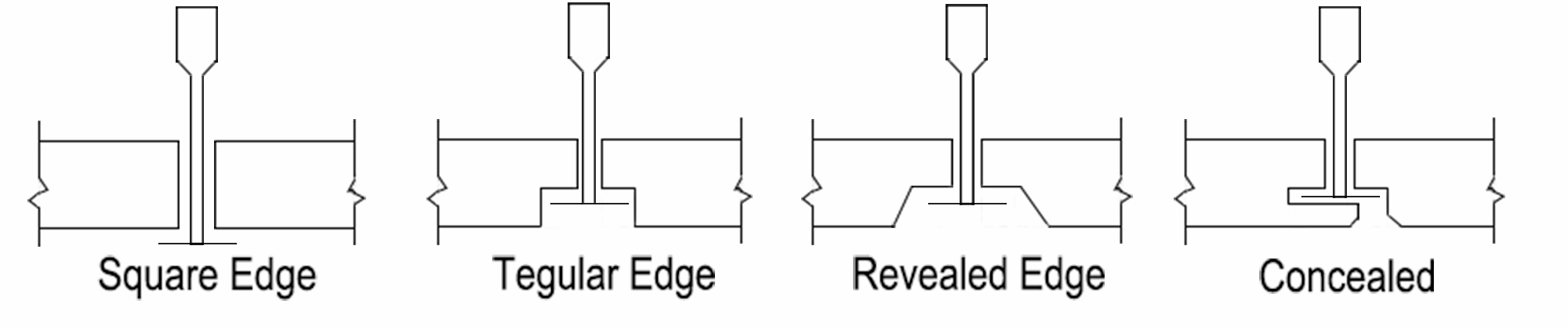

1. Before installation, pull the wire at the lower opening of the medium-sized light steel paint keel to control the straightness of the gap when the cover panel is installed.

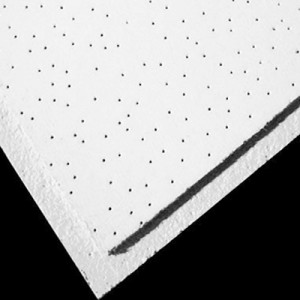

2. Adopt the compound paste installation method. On the installed U-shaped light steel keel ceiling frame, using self-tapping screws to fix the plasterboard on it first, level the seams and screw caps with putty, and then place the plasterboard Lay out the thread according to the size of the mineral wool board (500 or 600 square), and then apply glue on the back of the mineral wool board, spread 15 points, and finally paste the decorative sound-absorbing board on the paper gypsum board. Pay attention to the flat surface when pasting , the seam is straight.

3. During construction, pay attention to the direction of the white line, which must be consistent to ensure the integrity of the pattern and pattern.

4. Wearing clean gloves when installing the mineral wool board to avoid soiling the board surface.